FF-S-85D

3.6 Surface roughness. Unless otherwise specified (see 6.2), cap screws shall

have a maximum arithmetical average surface roughness on the bearing surface of

the head and shank of 125 microinches. Hot headed cap screws over 3/4 inch in

diameter are excepted and shall have a maximum surface roughness of 250

microinches. Threads shall have a maximum surface roughness of 63 microinches.

Normally, it will be sufficient to ascertain that these surfaces on screws have

the equivalent of a smooth machined finish by visual comparison with known surface

standards. However, then it is deemed necessary to measure these surfaces with

commercially available equipment, roughness measurements shall be taken axially on

the body and fillet surfaces, and circumferentially on the bearing surface in

accordance with ASME B46.1.

3.7 Method of manufacture. Unless the method of manufacture is specifically

stated (see 6.2), the method employed for the production of screw threads on cap

screws shall be at the option of the manufacturer.

3.8 Head markings. Steel cap screws shall be permanently marked with the grade

identification symbol conforming to SAE J429, and applicable documents. In

addition, all cap screws shall be marked with the manufacturer's identification

symbol.

Markings shall be located on the top of the head, and may be either

raised or depressed, at the option of the manufacturer.

Defects.

3.9

3.9.1 Discontinuities. Cap screws shall not contain discontinuities which

equal or exceed the following limitations. Care must be exercised not to confuse

cracks with discontinuities, as described herein. When visual inspection

discloses discontinuities which show cause for further examination, magnetic

particle or penetrant inspection as applicable, shall be as specified in 4.4.9.

3.9.1.1 Laps and seams. Cap screws may possess laps and seams except in

locations specified in 3.9.2. The depth shall not exceed that permitted in 3.9.2.

They shall be examined as specified in 4.4.9. Typical lap and seam

discontinuities are shown in figure 6.

3.9.1.2 Inclusions. Cap screws shall show no evidence of surface or subsurface

inclusions at the thread root when examined as specified in 4.4.9. Small

inclusions in other parts of the cap screws not indicative of unsatisfactory

quality, shall not be cause for rejection.

3.9.1.3 Tool marks. Tool marks or undercuts of depths not exceeding those

shown in table II and figure 8 are acceptable. Surface discontinuities such as

nicks, gouges, dents, scratches, and scrapes are permissible if they do not impair

the functionability of the product.

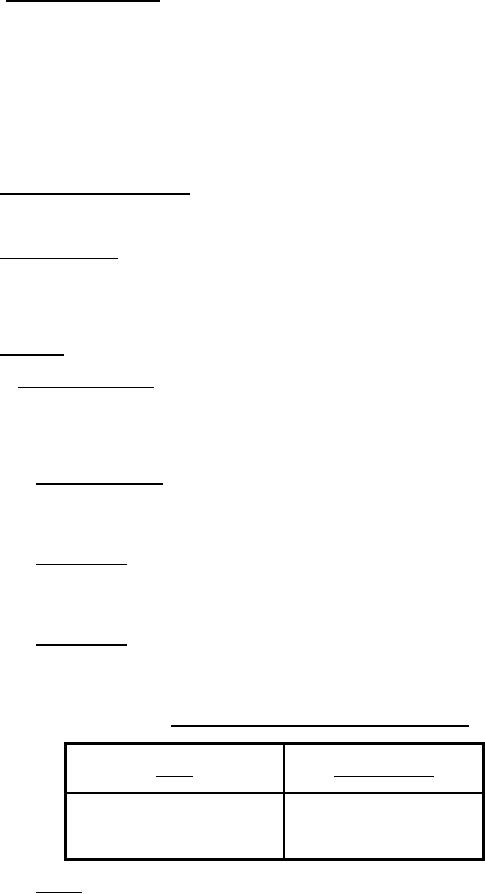

Limits of tool marks or undercuts.

TABLE II.

Depth

(Inch Max.)

Size

Up to 3/8 inch

0.003

Over 3/8 to 5/8 inch

0.004

Over 5/8 to 7/8 inch

0.005

Over 7/8 inch

0.006

3.9.1.4 Voids. Voids are permissible discontinuities if in the limits specified

in 4.4.9.2. Typical voids are shown in figure 8.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business