FF-S-85D

NASM51110

- Screw, Cap, Hexagon Head (Finished Hexagon Bolt), Shank

Drilled for Cotter Pin, Steel, Corrosion Resisting

Passivated, UNF-2A

NASM90725

- Screw, Cap, Hexagon Head (Finished Hexagon Bolt), Steel,

Grade 5, Cadmium Plated, UNC-2A

NASM90726

- Screw, Cap, Hexagon Head (Finished Hexagon Bolt), Steel,

Grade 5, Cadmium Plated, UNF-2A

(Application for copies of NASC publications should be addressed to the

Aerospace Industries Association, 1250 Eye Street, NW, Washington, DC 20005.)

3.

REQUIREMENTS

3.1 Material. Unless otherwise specified in the invitation for bids, contract

or order, cap screws shall be made of materials specified in 3.1.1 through 3.1.5

and Table IA (see 6.2).

3.1.1 Low carbon steel. Unless otherwise specified (see 6.2) grade 2 cap

screws shall be made of low carbon steel as shown in Table I. The chemical

composition shall contain a maximum of 0.28 percent carbon, a maximum of 0.04

percent phosphorus, and a maximum of 0.05 percent sulfur.

3.1.2 Medium carbon steel. Grade 5 cap screws shall be made of medium carbon

steel as shown in Table I and conforming to the requirements of SAE-AMS-STD-66.

The chemical composition shall contain 0.28 to 0.55 percent carbon, a maximum of

0.04 percent phosphorus and a maximum of 0.05 percent sulfur. It shall be

quenched and tempered at a minimum temperature of 800°F. Cap screws of the

following standards shall be made in accordance with the specification: MS35295,

NASM51095, NASM51096, NASM51105, NASM51106, NASM90725, and NASM90726.

Alloy steels.

3.1.3

3.1.3.1 Alloy steel, Grade 8. Grade 8 cap screws shall be made of alloy steel

as shown in Table I and conforming to the requirements of SAE-AMS-STD-66. The

chemical composition shall contain 0.28 to 0.55 percent carbon, a maximum of 0.04

percent phosphorus, and a maximum of 0.05 percent sulfur. It shall be hardened

sufficiently to a minimum oil-quench Rockwell hardness of C45 at the center of the

threaded section, one diameter from the end of the cap screw. Cap screws of the

following standards shall be made in accordance with the specification: MS35302,

MS51107, and MS51108.

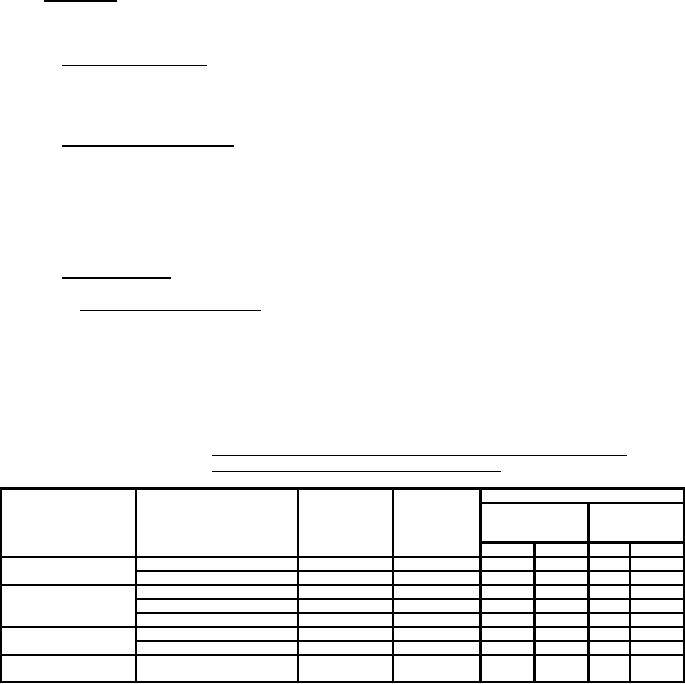

TABLE I.

Grades and Mechanical Properties of Steel Cap

Screws 1/4 thru 3 Inch Diameters

Hardness

Tensile

Strength

Proof Load

Nominal Size

Rockwell

Grade

Brinell No.

p.s.i. (Min)

p.s.i.

Dia., Inch

Designation

Min

Max

Min

Max

2

1/4 thru 3/4 *

55,000

74,000

149

241

B80

B100

Over 3/4 thru 1-1/2**

33,000

60,000

121

241

B70

B100

1/4 thru 1

85,000

120,000

255

321

C25

C34

5

Over 1 thru 1-1/2

74,000

105,000

223

285

C19

C30

Over 1-1/2 thru 3

55,000

90,000

183

235

B90

C21.7

8

1/4 thru 1-1/2

120,000

150,000

302

352

C33

C39

Over 1-1/2 thru 3

85,000

120,000

302

352

C33

C39

9

1/4 thru 1-1/2

130,000

170,000

336

386

C36

C45

(Option Alloy)

* 6" and less in length.

** All diameters if length exceeds 6".

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business